District heating: Difference between revisions

Centralized heat distribution system

District heating (also known as heat networks or teleheating) is a system for distributing heat generated in a centralized location through a system of insulated pipes for residential and commercial heating requirements such as space heating and water heating. The heat is often obtained from a cogeneration plant burning fossil fuels or biomass, but heat-only boiler stations, geothermal heating, heat pumps and central solar heating are also used, as well as heat waste from factories and nuclear power electricity generation. District heating plants can provide higher efficiencies and better pollution control than localized boilers. According to some research, district heating with combined heat and power (CHPDH) is the cheapest method of cutting carbon emissions, and has one of the lowest carbon footprints of all fossil generation plants.[1]

Fifth-generation district heat networks do not use combustion on-site and have zero emissions of CO2 and NO2 on-site; they employ heat transfer using electricity, which may be generated from renewable energy or from remote fossil-fuelled power stations. A combination of CHP and centralized heat pumps is used in the Stockholm multi-energy system. This allows the production of heat through electricity when there is an abundance of intermittent power production, and cogeneration of electric power and district heating when the availability of intermittent power production is low.[2]

District heating is ranked number 27 in Project Drawdown‘s 100 solutions to global warming.[3][4]

History[edit]

District heating traces its roots to the hot water-heated baths and greenhouses of the ancient Roman Empire. A hot water distribution system in Chaudes-Aigues in France is generally regarded as the first real district heating system. It used geothermal energy to provide heat for about 30 houses and started operation in the 14th century.[5]

The U.S. Naval Academy in Annapolis began steam district heating service in 1853.[citation needed] MIT began coal-fired steam district heating in 1916 when it moved to Cambridge, Massachusetts.[6][7]

Although these and numerous other systems have operated over the centuries, the first commercially successful district heating system was launched in Lockport, New York, in 1877 by American hydraulic engineer Birdsill Holly, considered the founder of modern district heating.

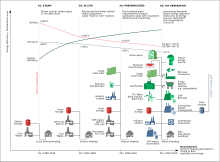

Generations of district heating[edit]

Generally, all modern district heating system are demand driven, meaning that the heat supplier reacts to the demand from the consumers and ensures that there is sufficient temperature and water pressure to deliver the demanded heat to the users. The five generations have defining features that sets them apart from the prior generations. The feature of each generation can be used to give an indication of the development status of an existing district heating system.

First generation[edit]

The first generation was a steam-based system fueled by coal and was first introduced in the US in the 1880s and became popular in some European countries, too. It was state of the art until the 1930s. These systems piped very high-temperature steam through concrete ducts, and were therefore not very efficient, reliable, or safe. Nowadays, this generation is technologically outdated. However, some of these systems are still in use, for example in New York or Paris. Other systems originally built have subsequently been upgraded.[8]

Second generation[edit]

The second generation was developed in the 1930s and was built until the 1970s. It burned coal and oil, and the energy was transmitted through pressurized hot water as the heat carrier. The systems usually had supply temperatures above 100 °C, and used water pipes in concrete ducts, mostly assembled on site, and heavy equipment. A main reason for these systems was the primary energy savings, which arose from using combined heat and power plants. While also used in other countries, typical systems of this generation were the Soviet-style district heating systems that were built after WW2 in several countries in Eastern Europe.[8]

Third generation[edit]

In the 1970s the third generation was developed and was subsequently used in most of the following systems all over the world. This generation is also called the “Scandinavian district heating technology”, because many of the district heating component manufacturers are based in Scandinavia. The third generation uses prefabricated, pre-insulated pipes, which are directly buried into…